ZF SERIES VACUUM PUMP UNIT

The ZF series vacuum pump station (also known as vacuum generating device, vacuum negative pressure station, etc.) is a complete system that uses one or two water ring vacuum pumps as vacuum acquisition equipment and vacuum tanks as vacuum storage equipment. For situations where frequent use of a vacuum source requires less pumping volume, this system is more efficient than directly using a vacuum pump...

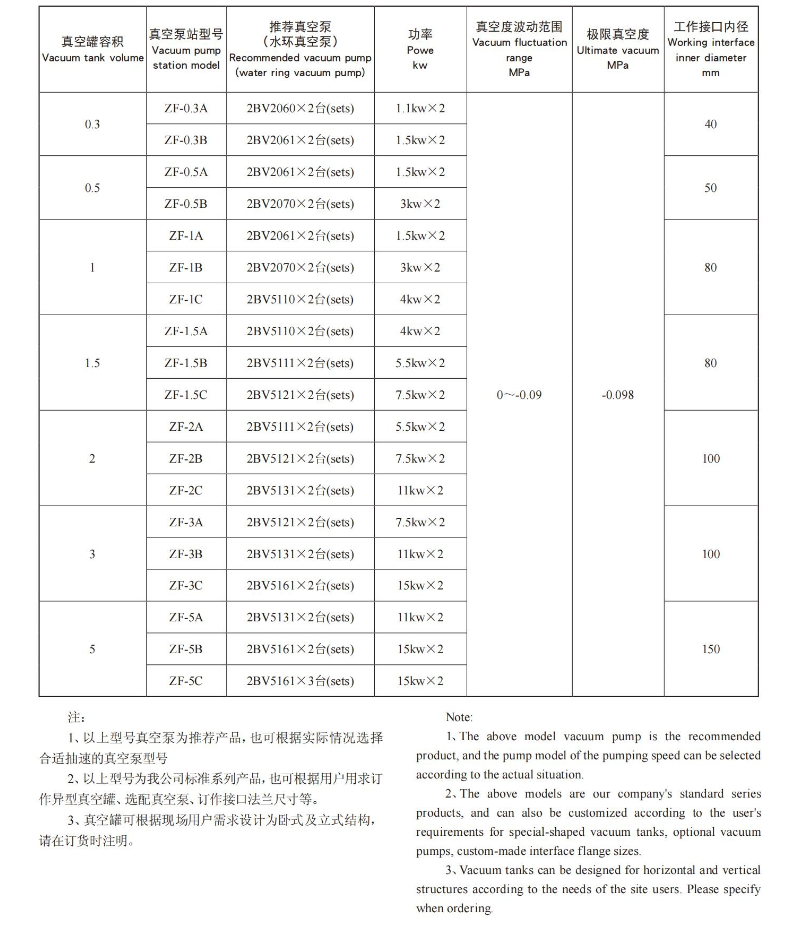

Performance rangeVacuum tank volume: 0.3-5 Power: 1.1KW-15KW Vacuum degree fluctuation range: 0-0.09MPa Ultimate vacuum degree:- 0.098MPa working interface inner diameter: 40-150mm

Application EnvironmentThis equipment can provide vacuum sources for medical gas center stations in various large and medium-sized hospitals in China, and is widely used in vacuum stations in the chemical and pharmaceutical industries, canning systems in the light industry, negative pressure forming of rubber and plastic engineering parts in the automotive industry, impregnation of flame-retardant conveyor belts in coal mines, and vacuum sources in the casting industry (V-method, VRH, V-EPC)

Hotline:8613021505120

The ZF series vacuum pump station (also known as vacuum generating device, vacuum negative pressure station, etc.) is a complete system that uses one or two water ring vacuum pumps as vacuum acquisition equipment and vacuum tanks as vacuum storage equipment. For situations where the vacuum source is frequently used and the required pumping volume is not too large, this system greatly saves energy compared to directly using a vacuum pump and effectively improves the service life of the vacuum pump.

This equipment can provide vacuum sources for medical gas center stations in various large and medium-sized hospitals in China, and is widely used in vacuum stations in the chemical and pharmaceutical industries, canning systems in the light industry, negative pressure forming of rubber and plastic engineering parts in the automotive industry, impregnation of flame-retardant conveyor belts in coal mines, and vacuum sources in the casting industry (V-method, VRH, V-EPC).

Performance characteristics:

After the first start-up, the entire operation process of the device can achieve fully automatic control. During its operation, the vacuum degree in various parts of the vacuum system always fluctuates up and down within its allowable range, and the fluctuation range can be adjusted according to user requirements.

The device automatically controls the system without human operation and can automatically close the vacuum system in case of power outage.

The device is equipped with a gas water separator, which can save water sources and reduce environmental pollution.

If the circulating wastewater cannot be discharged, adding a working fluid heat exchanger can achieve closed-loop circulation of the working fluid, thereby greatly reducing wastewater discharge.

The vacuum tank of this device can be designed as a horizontal or vertical structure according to the site, making installation more flexible.